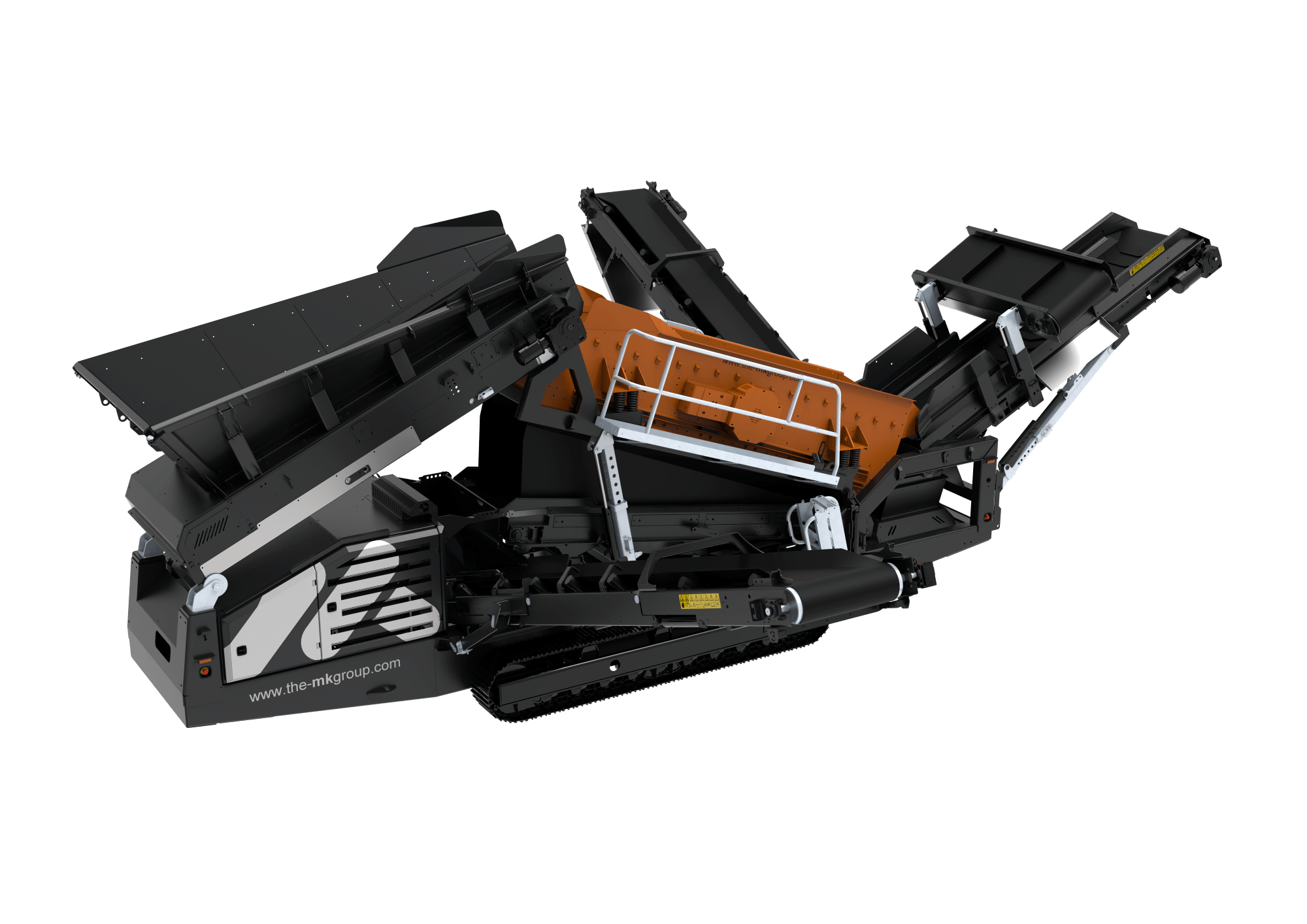

RS514T Track Recycling Screen

screen

Size material

tracked

Mobility = Versatility. Easy to Finance

Standalone / Combine

Can be used on its own or in conjunction with other M&K equipment to provide a total solution

Hybrid

Diesel-electric/Dual Powered, easy setup ensures the lowest cost of total ownership.

RS514T Hybrid Track Recycling Screen with Flip Flow Bottom Deck

The M&K RS514T is a HYBRID dual-power tracked recycling screen designed to separate waste material into two or three size fractions. Featuring a 3D top deck to prevent snagging and a Polyurethane Flip Flow bottom deck for fine screening, the RS514T is purpose-built for construction and demolition, municipal solid waste, and industrial recycling applications

Key Features & Benefits

- HYBRID Dual Power: Connect to mains electricity or run on the on-board 30kVA diesel generator — dramatically reducing running costs and CO2 emissions compared to traditional diesel-hydraulic machines.

- 3-Fraction Separation: The RS514T separates waste into three distinct size fractions (e.g. 0–10mm fines, 10–80mm mid-fraction, and 80mm+ oversize) in a single pass.

- Flip Flow Bottom Deck: Polyurethane Flip Flow mats in the bottom deck allow accurate screening down to fine sizes — ideal for sticky, wet, or difficult-to-screen materials.

- 3D Anti-Snagging Top Deck: Specially designed screen media prevents contamination of the mid-size fraction by long, fibrous material such as plastic film or wire.

- Built-in Overband Magnet: Ferrous metal recovery is integrated directly into the machine — no need for a separate magnet unit.

- Tracked Mobility: Self-propelled on rubber tracks for easy repositioning on site — no crane or low-loader required for relocation within a site.

- Touch Screen HMI: Simple and intuitive control via the on-board touch screen Human Machine Interface.

- Low Total Cost of Ownership: On-board stackers eliminate the need for additional conveyors; dual power reduces fuel costs; fewer moving parts than diesel-hydraulic competitors.

Company: RGS Nordic Location: Denmark (17 facilities)

Solution: Mobile integrated recycling system. RS514T + AS150T + PS312M

Result: 90%+ material recovery supporting Denmark’s 70% recycling target by 2030

Key Results

- 90%+ material recovery rate – Exceeding Denmark’s 70% national target

- 40-50 tons/hour processing capacity – Matching previous static plant

- Eliminated daily downtime – Previous system lost 2-3 hours daily to maintenance

- Multi-site deployment – Operating across 17 RGS Nordic facilities

- Operational in hours– Not months like static plant installation

- 5 waste streams processed – C&D, biomass, soil, gypsum, metals

- 60-70% CO2 reduction – When operating in electric mode

Custom Order

RS514T Track Recycling Screen

*All dimensions and weights are approximate. M&K reserves the right to alter specification without notice. Images may show optional equipment

SEWAGE CLEANING MEDIA WASHING SYSTEM

HEAVY DUTY FEEDER

LARGE CAPACITY

ANTI-SNAG TOP DECK

FLIP FLOW

HYRBID POWER

INTUITIVE CONTROL

C&D Waste | Skip Waste

C&D Waste | Skip Waste

Concrete Recycling

Landfill Mining

FREQUENTLY ASKED QUESTIONS

M&K dual power technology systems are designed to give users a choice between diesel and electric power. The machines can be run as standard diesel or connected to an external electricity supply.

Yes. The Recycling box can be swapped out for a quarry box very quickly & easily. The RS514T can then be repurposed to an application better suited to aggregates.

Yes. The RS514T is designed for waste and many waste operations occur on a site boundary or along the side of a building.

Yes as standard. And our Automation department can customise to whatever parameters you want/need

So far

3D anti Snag/Anti Long Piece Meshes

Punch Plate

Woven Mesh

Rubber Mats

Fingers

or combinations of the above

Yes.

The RS514T Hybrid Track Recycling Screen is a mobile waste separation solution that processes mixed materials into three clean size fractions. Material is loaded via the large capacity hopper and dual-drive chevron conveyor, preventing blockages common in waste recycling operations.

The material travels across a two-deck screening system. The top deck features 3D honeycomb media designed to prevent snagging from long pieces while the bottom deck uses polyurethane flip flow mats that excel at screening high-moisture materials. This combination ensures clean separation even with challenging waste streams.

Three independent discharge conveyors collect the separated fractions: fines (under-screen), mid-size product, and oversize material. Variable speed drives allow precise control of discharge rates, while the wing conveyors can both discharge to the same side for operations constrained by site boundaries.

Flip flow screening technology represents a breakthrough for waste recycling applications. Unlike traditional screening media, flip flow uses flexible polyurethane mats that actively flex during operation, preventing blinding and allowing you to screen down to smaller sizes even with wet, sticky materials.

Key advantages:

- Screen high-moisture content waste that would blind conventional screens

- Self-cleaning action reduces downtime and maintenance

- Achieve finer separations in challenging conditions

- Process filter media, compost, topsoil, and wet C&D waste effectively

- The RS514T combines flip flow on the bottom deck with anti-snag mesh on top, giving you the best of both technologies in one mobile unit.

The RS514T’s dual power system delivers operational flexibility and significant cost savings:

Electric Mode Benefits:

- Up to 70% reduction in operating costs vs diesel-only

- Significantly lower CO2 emissions for environmental compliance

- Quieter operation for urban and residential sites

- No AdBlue required (with Stage 5 Doosan engine option)

- Fewer moving parts means reduced maintenance

Diesel Mode Benefits:

- Complete site mobility without power infrastructure

- Quick setup and relocation

- Ideal for remote locations

Switch between power modes based on your site conditions and maximise profitability on every project.

The RS514T excels across multiple waste recycling and material processing applications:

- Construction & Demolition Waste | Skip Waste Recycling: Separate mixed C&D into clean aggregate, mid-fraction recyclables, and oversized debris. Process brick, concrete, wood, and mixed construction materials efficiently. Turn mixed skip waste into valuable products. Remove fines, separate recyclables, and create clean RDF or SRF feedstock.

- Soil & Compost. Screen topsoil, compost, and green waste. The flip flow bottom deck handles high-moisture organics that would blind traditional screens.

- Landfill Mining. Recover valuable materials from historic landfills. Process aged waste with high fines content and moisture.

- Aggregate Recycling. Clean recycled aggregates for resale. Remove contamination and create specification products.

- Filter Media Recovery. Water treatment plants use the RS514T to recycle filter media,Water Treatment Plants Slash Filter Media Costs by 90% significantly reducing disposal costs and fresh media purchases.

All the products it produces..fantastic!!!

RS514T + PS312M

RS514T + PS312M | Skip Waste

RS514T + PS312M + AS150T

Company: RGS Nordic Location: Denmark (17 facilities)

Solution: Mobile integrated recycling system. RS514T + AS150T + PS312M

Result: 90%+ material recovery supporting Denmark’s 70% recycling target by 2030

Key Results

- 90%+ material recovery rate – Exceeding Denmark’s 70% national target

- 40-50 tons/hour processing capacity – Matching previous static plant

- Eliminated daily downtime – Previous system lost 2-3 hours daily to maintenance

- Multi-site deployment – Operating across 17 RGS Nordic facilities

- Operational in hours– Not months like static plant installation

- 5 waste streams processed – C&D, biomass, soil, gypsum, metals

- 60-70% CO2 reduction – When operating in electric mode

RS5145T on Topsoil

RS5145T on Topsoil

RS514T on C&D

RS514T on C&D

RS514T on RDF

RS514T on RDF

Problems this machine has solved

Mobile Waste Recycling Equipment No Planning Permission

Read morePlasterboard Recycling Solution Transforming Construction Waste into Valuable Resources

Read moreBlysk Transforms Waste Management with M&K’s Cutting-Edge Mobile Recycling Technology

Read moreRecycling Filter Media Saves Water Treatment Plants Money

Read moreAdditional Information

M&K is the leading supplier of innovative static, mobile and modular waste recycling and material handling technology combining unparalleled technological manufacturing capabilities with decades of application expertise. Established in 1977, M&K design, manufacture & support static, mobile and modular Shredders, Trommels, Recycling Screens, Star Screens, Conveyors, Picking Cabins, Air Separators, Crushers & Washing Systems.

To learn more, click here, for a no obligation discovery call book a time here, or call/What’s App now on +447786561002

Solves problems in

We have supplied this solution to help customers build profitability in the following:

Works Great With

Other recycling products in M&K’s range to provide an easy, fast & hassle free ways of processing waste. #recyclingmadeeasy