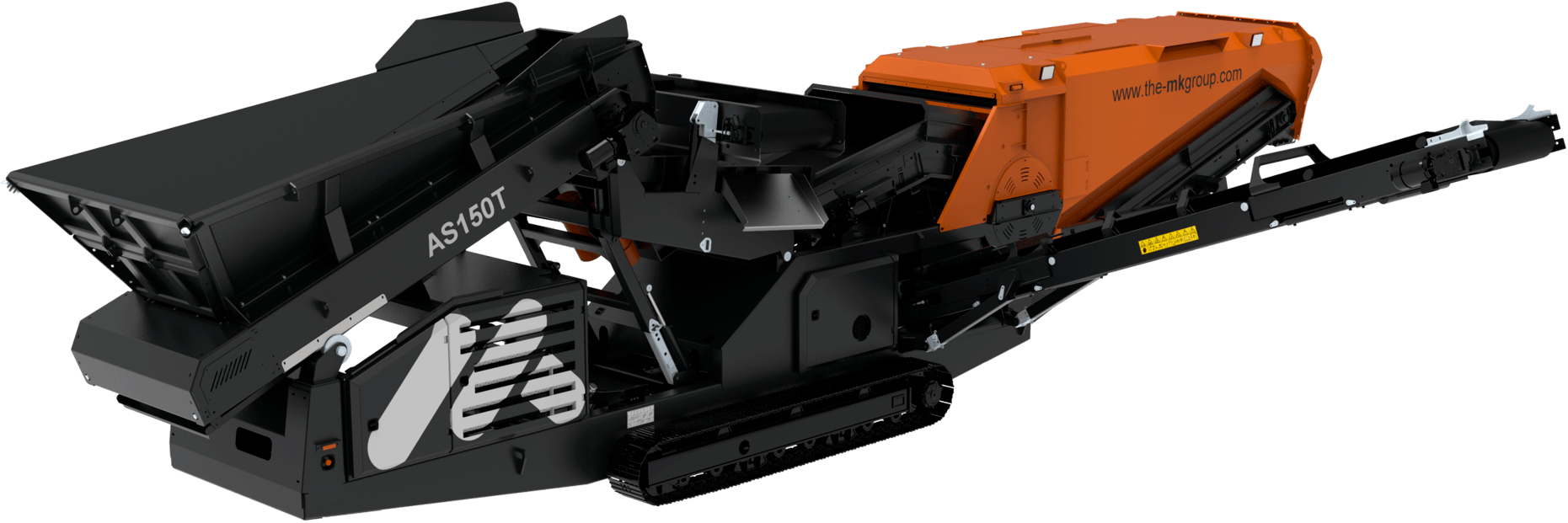

AS150T Track Air Density Separator

separate

Separates by Density. Heavy Density & Light Density

tracked

Mobility = Versatility. Easy to Finance

Standalone / Combine

Can be used on its own or in conjunction with other M&K equipment to provide a total solution

Hybrid

Diesel-electric/Dual Powered, easy setup ensures the lowest cost of total ownership.

AS150T Track Air Density Separator

AS150T Track Air Density Separator is a HYBRID Single Drum Air Density Separator

The AS150T will separate light fraction from heavy fraction.

WHY DO YOU NEED THIS MACHINE?

- Improve your product quality

- Remove unwanted heavy materials

- Prevents damage to your shredder

- Reduce downtime and maintenance costs by eliminating blockages and wear-and-tear.

- Promotes energy savings by optimizing material flow and reducing load on your conveying system.

HOW DOES THE AS150T WORK?

The AS150T Track Air Density Separator achieves an accurate separation by presenting the infeed material to the air separation chamber in a mono layer.

- Belt Feeder | Low Feed Height | Accommodates surges from downstream | Enables the AS150T to be used as a standalone unit

- Vibrating Feeder | creates a mono layer

- Acceleration Belt | Evenly spread material is accelerated toward the Air Separation Chamber

- Air Separation Chamber | Variable speed blowers and an adjustable nozzle produce are air stream that carries light materials upwards and over the separation drum.

- Separation Drum | Variable Speed

- Suction Fan | Maintains stable air velocity to prevent contamination

- Dual Power Ready – Connect directly to the mains supply energy

- Simple & Intuitive Control

- Design & Support by M&K

AS150T Air Density Separator Features

| Module | Specification | |

|---|---|---|

| Feed Conveyor & Hopper | 1300mm Chevron Dual Drive VSD Folding Back Plate | Large Capacity, Blockage Free |

| Vibrating Feeder | 1400mm Stainless Steel Hyd Angle Adjustment Wear Plates VSD | |

| Magnet | Overband Magnet 300mm working gap Bi Directional. Hydraulic Height Adjustment | Optional |

| Accelerator Belt | Adjustable In & Out Adjustable Up & Down Impact Bars Plain Belt VSD | |

| Air Separation Module | 2 X 11kw Blowers Adjustable Nozzle VSD | |

| Splitter Drum | 700mm Dia Splitter Drum Variable Speed from HMI. | |

| Decompression Chamber | 18kw VSD | |

| Lights Conveyor | Belt Type: Plain | |

| Heavy Fraction Conveyor | Impact Bars Hydraulic Folding LH or RH VSD | |

| Powerpack | Dual Power 66Kva Generator 30kW Hydraulic PowerPack | Dual Power Ready - Connect directly to the mains supply energy Less moving parts compared to Diesel Hydraulic meaning less things to go wrong and less parts to maintain. Cheaper Running Costs than Diesel Hydraulic Electric is significantly greener than traditional Diesel Hydraulic producing less CO2. Design & Support by M&K |

| Automation & Control | Touch Screen HMI | Simple & Intuitive Control PLC Design By M&K Siemens HMI AutoStart sequential start. AutoStop sequential stop Fault Finding Designed & Support by M&K |

| Working | Width (m) : 2.9 Length (m) : 15.5 Height (m) : 3.2 | Weight (kgs) : 25,000 * |

| Transport | Width (m) : 8.3 Length (m) : 15.3 Height (m) : 3.2 | Weight (kgs) : 24,000 * |

| OPTIONS | ||

| Engine | Doosan Stage 5 (No AdBlue) | |

| Radio Control | Radio Control | |

| Air | Suction System | 30 kW | External Power Source Required | |

| Magnet | Drum Magnet on Residual Conveyor | |

| PAS | Positive Air Pressure System for Control Panel | |

| PAS | Positive Air Pressure System for Control Panel | |

| Compressor | Compressor | |

| Conveyor | Collection conveyor for No Fe | |

*All dimensions and weights are approximate. M&K reserves the right to alter specification without notice. Images may show optional equipment

RDF

Landfill Mining

M&K is the leading supplier of innovative static, mobile and modular waste recycling and material handling technology combining unparalleled technological manufacturing capabilities with decades of application expertise. Established in 1977, M&K design, manufacture & support static, mobile and modular Shredders, Trommels, Recycling Screens, Star Screens, Conveyors, Picking Cabins, Air Separators, Crushers & Washing Systems.

To learn more, click here, for a no obligation discovery call book a time here, or call/What’s App now on +447786561002.

Applications

We’ve supplied these machines to solve problems to organisations working in…

Works a treat with

Other recycling products in M&K’s range to provide an easy, fast & hassle free ways of processing waste. #recyclingmadeeasy